United Nations Video: Bangladesh, Myanmar, Geneva & other topics - Daily Press Briefing (14 March 2025) | United Nations

Noon Briefing by Stéphane Dujarric, Spokesperson for the Secretary-General.

Highlights:

- Secretary-General/Bangladesh

- Myanmar

- Trip Announcement / Geneva

- Trip Announcement / Brussels

- Democratic Republic of the Congo

- Central African Republic

- Occupied Palestinian Territory

- Syria

- Global Trade 2025

- Coffee Prices

- Islamophobia

- Commission on the Status of Women

SECRETARY-GENERAL/BANGLADESH

The Secretary-General today was in Cox’s Bazaar, Bangladesh, as part of his Ramadan solidarity visit with Rohingya refugees and their Bangladeshi host communities.

The Secretary-General had the chance to meet with refugees, many of them young men and women, who told him about their experiences and concerns. He spoke to children who were grateful to be able to go to school in the camps, but missed their homes in Myanmar. And he met young people who still have hope to return to their homeland but are also worried about the impending funding cuts which would dramatically reduce their monthly food rations (from $12.50 to $6 per month). The Secretary-General also visited a jute center, where he had a chance to hear from women who are trying to build a livelihood inside the camps.

The Secretary-General assured every one of the people he met that he would do everything he can to stop the funding cuts, and he apologized to them because the UN and the international community have not been able to stop the conflict in Myanmar.

He later had a press encounter in which he said that he had heard two clear messages: first, Rohingyas want to go back to Myanmar; and second, they want better conditions in the camps.

And at sunset, he shared an Iftar with some 60,000 refugees. He told them that sharing an Iftar with them is a symbol of his deep respect for their religion and their culture. He also said that we are facing a deep humanitarian crisis with the announced funding cuts, and he lamented that as a result, many people will suffer, and some people might die.

“My voice will not end until the international community understands that they have the obligation to invest now in the Rohingya refugees,” he said.

Chief Adviser Muhammad Yunus was also present at the Iftar, and they met separately earlier in the day.

MYANMAR

The World Food Programme today warned that more than one million people in Myanmar will be cut off from its food assistance starting in April – due to critical funding shortfalls.

WFP says these cuts come just as increased conflict, displacement and access restrictions are already sharply driving up food aid needs.

Without immediate new funding WFP will only be able to assist 35,000 of the most vulnerable people, including children under the age of five, pregnant and breastfeeding women, and people living with disabilities.

The cuts will also impact almost 100,000 internally displaced people in central Rakhine who will have no access to food without WFP assistance, including Rohingya communities in camps.

WFP urgently needs US$ 60 million to maintain its life-saving food assistance to the people of Myanmar this year.

Optional - A staggering 15.2 million people are unable to meet their minimum daily food needs in Myanmar, according to the Myanmar Humanitarian Needs and Response Plan; this is up from 13.3 million last year. Of these, according to the plan, some 2.3 million people are facing emergency levels of hunger. Even with regular support, these families who rely solely on WFP food assistance, are already reporting skipping meals, selling properties or going into debt just to survive.

TRIP ANNOUNCEMENT / GENEVA

On Sunday, the Secretary-General will arrive in Geneva, Switzerland, where, as we announced a few days ago, he is convening the two Cypriot leaders and the Guarantor Powers of Greece, Türkiye and the United Kingdom for an informal meeting on Cyprus at the United Nations Office in Geneva.

The meeting will take place from 17 to 18 March and is being held in the context of the Secretary-General’s good offices efforts on the Cyprus issue and as agreed with the two leaders on 15 October 2024.

The informal meeting will provide an opportunity for a meaningful discussion on the way forward on the Cyprus issue. The United Nations remains committed to supporting the Cypriot leaders and all Cypriots.

Full Highlights: https://www.un.org/sg/en/content/noon-briefing-highlight?date%5Bvalue%5D%5Bdate%5D=14%20March%202025

Published: 14th Mar 2025 06:49:53 By: United NationsUnited Nations Video: Doctors Without Borders on the war in Sudan - Security Council Media Stakeout | United Nations

Comments to the media by Christopher Lockyear, secretary general of Doctors Without Borders/Médecins Sans Frontières (MSF) on the situation in Sudan and South Sudan.

Published: 13th Mar 2025 07:24:49 By: United NationsUnited Nations Video: Syria, Sudan/Security Council & other topics - Daily Press Briefing | United Nations

Noon Briefing by Stéphane Dujarric, Spokesperson for the Secretary-General.

Highlights:

Secretary-General

Syria

Treaty on state border between the Kyrgyz Republic and the Republic of Tajikistan

Haiti

Sudan/Security Council

Sudan / Humanitarian

Occupied Palestinian Territory

Yemen

Bosnia and Herzegovina

Ethiopia

Measles / European Region

Journalism Fellowship

SECRETARY-GENERAL The Secretary-General just arrived in Dhaka, Bangladesh, to start off his Ramadan solidarity visit. Tomorrow, he will meet with the Chief Adviser of the government, Muhammad Yunus and travel with him to Cox’s Bazaar. They will meet there with Rohingya refugees who have been forcibly displaced from their homes in Myanmar and also, they will meet with the host Bangladeshi communities who have been so generous in hosting them. The Secretary-General will also share an Iftar with the refugees, and he will also issue a call to the international community to step up their humanitarian assistance for these men, women and children who have already suffered so much. And on Saturday in Dhaka, the Secretary-General will meet with youth and representatives from civil society. He will also have a joint press conference with the Foreign Adviser, Touhid Hossain.

SYRIA Following the Constitutional Declaration issued by the Caretaker Authorities in Syria, the Special Envoy for Syria, Geir Pedersen, said he welcomes moves toward restoring the rule of law and notes that this development potentially fills an important legal vacuum. The Special Envoy hopes the declaration can be a solid legal framework for a genuinely credible and inclusive political transition. Proper implementation will be key, he said, along with continued efforts to ensure transitional governance in an orderly manner. In a statement, the Secretary-General said that 14 years have now passed since the Syrian people stood up in peaceful protest for their universal rights and freedoms, only to be met with brutal repression. Mr. Guterres added that what began as a call for peaceful change turned into one of the world’s most devastating conflicts, with an incalculable human cost. The Secretary-General spoke about the millions of men, women and children who were displaced and subjected to unimaginable hardship. Yet, the Syrian people never wavered in their steadfast and courageous calls for freedom, for dignity, and for a just future. Since 8 December, however, we saw renewed hope that Syrians can chart a different course and the chance to rebuild, the chance to reconcile, and the chance to create a nation where they can all live peacefully and in dignity. The Secretary-General said nothing can justify the killing of civilians, that we have been reporting in recent days. He stressed that all violence must stop, and there must be a credible, an independent, an impartial investigation of violations and those responsible must be held to account. He added that the caretaker authorities have repeatedly committed to building a new Syria based on inclusive and credible foundations for all Syrians. Now is the time for action, he said. He concluded by reiterating that we stand ready to work alongside the Syrians and support an inclusive political transition and we stand with the Syrian people towards the promise of a better Syria – for all Syrians.

TREATY ON STATE BORDER BETWEEN THE KYRGYZ REPUBLIC AND THE REPUBLIC OF TAJIKISTAN The Secretary-General warmly welcomes the signing of the Treaty on the State Border by the Presidents of the Kyrgyz Republic and the Republic of Tajikistan, and that took place today in Bishkek. He congratulates the two countries on this historic achievement and commends their leadership, their determination and their political will to bring the decades-long negotiation process to a successful conclusion. The Secretary-General looks forward to a sustained constructive engagement between the two countries towards fostering mutual trust, good-neighbourly relations and a peaceful future for their people and the broader region.

Full Highlights: https://www.un.org/sg/en/content/noon-briefing-highlight?date%5Bvalue%5D%5Bdate%5D=13%20March%202025

Published: 13th Mar 2025 07:24:27 By: United NationsUnited Nations Video: Humanitarian worker: Overstretched and Under-resourced - Press Conference | United Nations

Press Conference by Tom Fletcher, Under-Secretary-General for Humanitarian Affairs and Emergency Relief Coordinator, on

--------------------------------------------

UN Emergency Relief Coordinator Tom Fletcher said, “The pace and the scale of the funding cuts that we've faced are, of course, a seismic shock” to the humanitarian sector.

Addressing the press, Fletcher said, “We were already overstretched, under-resourced, and literally under attack with last year being the deadliest year on record to be a humanitarian worker. But of course, it's far tougher for the people who we serve. 300 million plus right now need humanitarian support.”

He stressed, “Many will die because that aid is drying up. And across the humanitarian community, programs are being stopped right now. Staff are being let go right now; I think 10 percent of NGO colleagues were laid off in the course of February. And across the UN family and our partners, we're making tough choices day to day about which lives we will have to prioritize, which lives we have to try to save. And so, I think this period ahead, the weeks actually ahead will define how we emerge as a humanitarian movement from this sustained challenge.”

He said, “I'll receive at the end of this week, on Friday, detailed plans from all of our humanitarian coordinators. So, the lead humanitarian official in each of our crisis countries, drawn together by their humanitarian country team across agencies and NGOs on how they will change their strategies to make this new challenge.”

He continued, “But behind that regrouping, we'll also have to renew what we do as well. We'll have to build fresh arguments, fresh allies for our work. We'll have to find new sources of funding. We'll have to fight back. We'll have to reimagine what we do, and - this is an important point and easy thing to say, much harder to actually deliver - we will have to shift power towards our humanitarian leaders in country and towards the people that we serve, the communities that we work with on the frontlines of the humanitarian crisis.”

He added, “So, we need a humanitarian decade, we'll have to win afresh that argument for humanitarian and international solidarity. And that is a cause which I believe is mightier than year to year fluctuations and political changes.”

He highlighted, “We have been reliant in recent years – over reliant - on US funding. Almost half of our appeals have been funded by the American taxpayers. And it is important to recognize that we shouldn't ever take that for granted. Particularly, in a period of economic difficulty and in a period when, when many governments are in retreat from the world.”

Answering a question, he said, “I can't put a precise number on what the US cuts, the difference that would make. But what I can say is that over years and decades now, the US has been a humanitarian superpower, and the US funding has saved hundreds of millions of lives. And so, I hope that over time, we can make the case afresh for why that work is so important, and that we can ensure that funding is resumed so we can carry on saving that number of lives.”

Published: 13th Mar 2025 01:25:52 By: United NationsUnited Nations Video: United Kingdom on Iran's Non-proliferation- Security Council Media Stakeout | United Nations

Comments to the media by James Kariuki, Deputy Permanent Representative of the United Kingdom to the United Nations, before the closed consultations of the Security Council on Non-proliferation.

Published: 12th Mar 2025 07:25:04 By: United Nations

CNN Video: DHS official unable to answer 'basic questions' on Mahmoud Khalil

Former GOP congressman Adam Kinzinger joins "Table for Five" to discuss an NPR interview with Deputy DHS Secretary Troy Edgar about the arrest of Palestinian refugee Mahmoud Khalil, whose green card was revoked over last spring's Columbia University protests. Khalil remains in ICE custody in Louisiana. Watch the full episode of “Table for Five” with Abby Phillip Saturday, March 15 at 10 ET.

Published: 15th Mar 2025 02:14:04 By: CNNCNN Video: Anderson Cooper: Trump took a victory lap at Department of Justice

President Donald Trump excoriated the Justice Department prosecutors who investigated him and vowed to use it to target his own enemies in a campaign-style speech at the department’s historic Great Hall.

The hourlong speech served as both a victory lap for beating the two federal criminal cases brought against him by the Biden administration, and as a condemnation against any officials – some of whom have been fired from the DOJ – who touched those cases.

#CNN #News

Published: 15th Mar 2025 01:58:43 By: CNNCNN Video: 'Survivor' contestant on his stutter

'Survivor' host Jeff Probst asked competitor Mitch Guerra a question about his stutter that captured the hearts of so many across the country. Guerra spoke with CNN about what that moment meant to him and how he hopes going on national television with a stutter will empower others with speech impediments.

Published: 14th Mar 2025 11:08:35 By: CNNCNN Video: Video of Mahmoud Khalil’s arrest released

In newly released video of Mahmoud Khalil's arrest, we hear his wife, Noor Abdalla, begging for information from officers. Abdalla, who is eight months pregnant, recorded the video, according to a post shared on Instagram by the ACLU.

#cnn #news #mahmoudkhalil

Published: 14th Mar 2025 10:35:34 By: CNNCNN Video: How a notorious military contractor got back in Trump’s orbit

Erik Prince has long been a controversial outside figure in President Trump’s extended political orbit. The security contractor first gained notoriety during the Iraq War when his contracting firm Blackwater provoked outrage after a deadly 2007 shooting that killed Iraqi civilians. Viewed as a pariah by some senior officials by the end of Trump’s first term, CNN reporting has uncovered a far more influential role in first months of Trump’s second term. #CNN #News #trump #erikprince

Published: 14th Mar 2025 09:51:28 By: CNN

BBC News Video: Tesla shares plunge as Elon Musk’s company raises alarm about Trump’s trade tariffs | BBC News

Shares in Tesla, the electric vehicle-maker owned by Elon Musk, have plunged, losing all the gains they have mades since Donald Trump’s election victory.

Investors are concerned about plunging sales figures which come as Tesla’s CEO Elon Musk is playing a divisive role in as a member of the Trump administration.

It’s emerged that Tesla has sent an unsigned letter to US trade officials that Trump’s tariffs risk provoking punishing retaliatory tariffs from other countries against US carmakers that may damage sales.

The letter says that Tesla “supports fair trade” but that the US administration should ensure it does not “inadvertently harm US companies”.

Clive Myrie presents BBC News at Ten reporting by Lily Jamali in San Francisco.

Subscribe here: http://bit.ly/1rbfUog

For more news, analysis and features visit: www.bbc.com/news

#BBCNews

Published: 14th Mar 2025 10:28:49 By: BBC NewsBBC News Video: Sea levels rose more than expected in 2024 | BBC News

Nasa says global sea levels rose by more than expected last year.

The water level was expected to rise around 0.43cm, but instead reached 0.59cm.

The agency blamed an unusual amount of ocean warming combined with water from melting glaciers.

2024 was the hottest year on record, with average global temperatures around 1.6C higher than pre-industrial times.

Subscribe here: http://bit.ly/1rbfUog

For more news, analysis and features visit: www.bbc.com/news

#ClimateChange #BBCNews

Published: 14th Mar 2025 09:30:09 By: BBC NewsBBC News Video: Can the Prime Minister change how the UK works? | BBC Newscast

Adam Fleming, Vicki Young, Faisal Islam and Nick Watt discuss UK Prime Minister, Sir Keir Starmer’s attempts to rewire the workings of the UK government by scrapping NHS England and reforming the welfare system. Plus is the Prime Minister going to push back more on President Trump as American tariffs on UK aluminium and steel imports come into effect.

Subscribe here: http://bit.ly/1rbfUog

For more news, analysis and features visit: www.bbc.com/news

#BBCNews #bbcnewscast #uk #ukpolitics #health #benefits #welfare

Published: 14th Mar 2025 07:30:07 By: BBC NewsBBC News Video: Mark Carney sworn in as Canadian prime minister | BBC News

Mark Carney said "negativity won't win a trade war" in his first speech as Canada's new prime minister, as the country faces a tariff standoff with US President Donald Trump.

Carney says he will visit France and the UK on his first overseas trip in the job, adding that he currently has "no plans" to meet Trump, but "looks forward" to speaking to him.

When asked about US Secretary of State Marco Rubio's latest comment saying that "economically speaking Canada would be better as the 51st state of the United States", Carney called it "crazy".

Subscribe here: http://bit.ly/1rbfUog

For more news, analysis and features visit: www.bbc.com/news

#MarkCarney #Canada #BBCNews

Published: 14th Mar 2025 07:28:47 By: BBC NewsBBC News Video: Thousands begin celebrating Holi 2025. #Holi #BBCNews

Published: 14th Mar 2025 04:30:18 By: BBC News

Published: 14th Mar 2025 04:30:18 By: BBC News

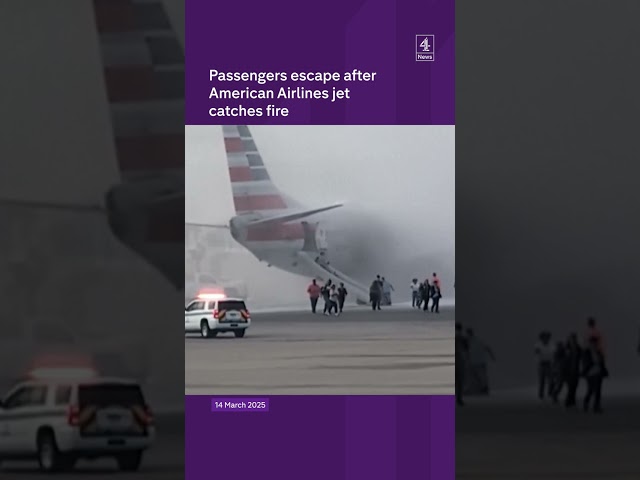

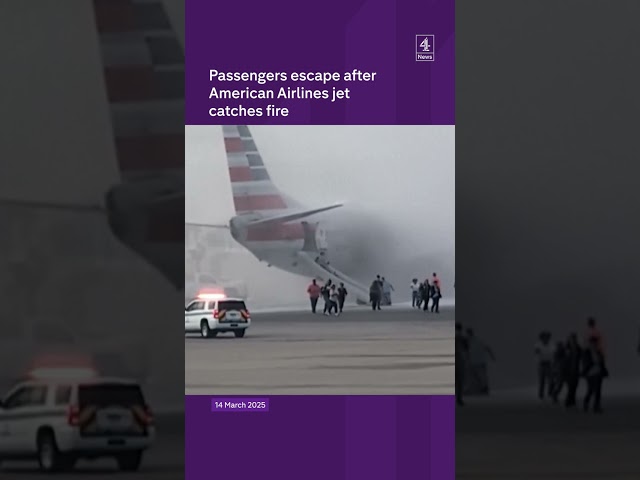

ODN Video: Passengers Forced to Evacuate on Wing of Burning American Airlines jet

This video shows the terrifying moment passengers were forced to evacuate an American Airlines jet, after the plane caught fire on the runway at Denver International Airport.

Some people were forced onto the wing of the aircraft to escape the flames, while others used inflatable slides to reach the tarmac.

12 people were taken to hospital with minor injuries, but there were no fatalities.

Subscribe here: http://bit.ly/ODNsubs

TikTok: https://www.tiktok.com/@ondemandnews

Twitter: https://twitter.com/ODN

Facebook: https://www.facebook.com/ODN/

If you wish to purchase any of our clips for commercial use, please visit: http://www.itnproductions.co.uk/news/

Published: 14th Mar 2025 11:53:08 By: On Demand NewsODN Video: Putin Responds to Ceasefire Proposal as Russian Forces Advance in Kursk

The Kremlin has released footage of the moment Russian President Vladimir Putin visited a military command centre in the Kursk region for the first time since Ukraine’s incursion.

Parts of the region have been occupied by the Ukrainian army since August after Kyiv launched an unexpected cross-border offensive.

But Russia has said its soldiers are close to completely driving out Ukrainian troops from their last foothold, Sudzha.

It comes as Putin has said conditions of the ceasefire deal with Ukraine needs to be worked out.

#ukraine #russia #kursk

Subscribe here: http://bit.ly/ODNsubs

TikTok: https://www.tiktok.com/@ondemandnews

Twitter: https://twitter.com/ODN

Facebook: https://www.facebook.com/ODN/

If you wish to purchase any of our clips for commercial use, please visit: http://www.itnproductions.co.uk/news/

Published: 13th Mar 2025 05:18:13 By: On Demand NewsODN Video: Inside China, Russia, and Iran's Massive Military Exercise in the Gulf of Oman

China, Russia, and Iran have finished the main phase of their joint naval exercise, ‘Security Belt-2025’ with their warships docking at Iran’s Chabahar Port on Tuesday.

The drills took place in the Gulf of Oman near the Strait of Hormuz, a crucial route for global oil shipments.

Warships from all three nations practised targeting threats at sea, boarding and inspecting vessels, damage control, and search and rescue missions.

On Monday, the fleets moved to the exercise zone, where China took command of a live-fire drill at night.

Their ships, along with Russian and Iranian vessels, carried out coordinated shooting exercises and machine gun drills at sea.

Subscribe here: http://bit.ly/ODNsubs

TikTok: https://www.tiktok.com/@ondemandnews

Twitter: https://twitter.com/ODN

Facebook: https://www.facebook.com/ODN/

If you wish to purchase any of our clips for commercial use, please visit: http://www.itnproductions.co.uk/news/

Published: 13th Mar 2025 01:57:58 By: On Demand NewsODN Video: Pakistan Train Hijack: Footage Shows Final Group of Rescued Hostages

This is the moment the last group of rescued hostages arrived at Mach railway station, escorted by security forces after a deadly standoff with militants.

The Jaffar Express was traveling from Quetta to Peshawar on 11th March, when gunmen from the Balochistan Liberation Army (BLA) launched an attack near the Bolan Pass.

Explosives were used to stop the train before militants opened fire, reportedly killing at least 20 people.

Over 400 passengers were taken hostage, including women, children, and reportedly military personnel.

#pakistan #pakistannews #breakingnews

Subscribe here: http://bit.ly/ODNsubs

TikTok: https://www.tiktok.com/@ondemandnews

Twitter: https://twitter.com/ODN

Facebook: https://www.facebook.com/ODN/

If you wish to purchase any of our clips for commercial use, please visit: http://www.itnproductions.co.uk/news/

Published: 13th Mar 2025 01:04:31 By: On Demand NewsODN Video: Footage Captures Russian Troops Retaking Sudzha in Kursk Region

CCTV footage released by local media shows alleged Russian soldiers raising the flag in Sudzha.

Kyiv forces seized the town in the Kursk region last August, as part of a surprise cross-border offensive.

But after seven months of control, the Russian army has claimed it made significant new gains in the region saying it captured more than 100 square kilometres of territory and five settlements.

#ukraine #russia #kursk

Subscribe here: http://bit.ly/ODNsubs

TikTok: https://www.tiktok.com/@ondemandnews

Twitter: https://twitter.com/ODN

Facebook: https://www.facebook.com/ODN/

If you wish to purchase any of our clips for commercial use, please visit: http://www.itnproductions.co.uk/news/

Published: 12th Mar 2025 07:00:50 By: On Demand News

CBC Video: More U.S. tariffs are coming. So are Chinese ones | Hanomansing Tonight

China says it will impose a 25 per cent tariff on Canadian seafood exports effective March 20 as a retaliatory measure to Canadian tariffs on steel, aluminum and electric vehicles last year. Geoduck harvester Darrell Thomas discusses how the tariffs could impact his business.

»»» Subscribe to CBC News to watch more videos: http://bit.ly/1RreYWS

Connect with CBC News Online:

For breaking news, video, audio and in-depth coverage: http://bit.ly/1Z0m6iX

Follow CBC News on TikTok: https://bit.ly/3TnHioe

Follow CBC News on Twitter: http://bit.ly/1sA5P9H

Find CBC News on Facebook: http://bit.ly/1WjG36m

Follow CBC News on Instagram: http://bit.ly/1Z0iE7O

Subscribe to CBC News on Snapchat: https://bit.ly/3leaWsr

Download the CBC News app for iOS: http://apple.co/25mpsUz

Download the CBC News app for Android: http://bit.ly/1XxuozZ

»»»»»»»»»»»»»»»»»»

For more than 80 years, CBC News has been the source Canadians turn to, to keep them informed about their communities, their country and their world. Through regional and national programming on multiple platforms, including CBC Television, CBC News Network, CBC Radio, CBCNews.ca, mobile and on-demand, CBC News and its internationally recognized team of award-winning journalists deliver the breaking stories, the issues, the analyses and the personalities that matter to Canadians.

Published: 15th Mar 2025 12:47:53 By: CBC NewsCBC Video: What's it like to work with Mark Carney? We asked a former colleague | Hanomansing Tonight

We asked Mark Carney's former colleague what it was like to work with him. Former central banker Miville Tremblay describes him as no-nonsense, demanding and strategic.

»»» Subscribe to CBC News to watch more videos: http://bit.ly/1RreYWS

Connect with CBC News Online:

For breaking news, video, audio and in-depth coverage: http://bit.ly/1Z0m6iX

Follow CBC News on TikTok: https://bit.ly/3TnHioe

Follow CBC News on Twitter: http://bit.ly/1sA5P9H

Find CBC News on Facebook: http://bit.ly/1WjG36m

Follow CBC News on Instagram: http://bit.ly/1Z0iE7O

Subscribe to CBC News on Snapchat: https://bit.ly/3leaWsr

Download the CBC News app for iOS: http://apple.co/25mpsUz

Download the CBC News app for Android: http://bit.ly/1XxuozZ

»»»»»»»»»»»»»»»»»»

For more than 80 years, CBC News has been the source Canadians turn to, to keep them informed about their communities, their country and their world. Through regional and national programming on multiple platforms, including CBC Television, CBC News Network, CBC Radio, CBCNews.ca, mobile and on-demand, CBC News and its internationally recognized team of award-winning journalists deliver the breaking stories, the issues, the analyses and the personalities that matter to Canadians.

Published: 15th Mar 2025 12:27:03 By: CBC NewsCBC Video: How will Carney as PM change the upcoming election? | Hanomansing Tonight

Prime Minister Mark Carney has slimmed down his cabinet and killed the consumer carbon tax. What does it mean for this year's federal election?

»»» Subscribe to CBC News to watch more videos: http://bit.ly/1RreYWS

Connect with CBC News Online:

For breaking news, video, audio and in-depth coverage: http://bit.ly/1Z0m6iX

Follow CBC News on TikTok: https://bit.ly/3TnHioe

Follow CBC News on Twitter: http://bit.ly/1sA5P9H

Find CBC News on Facebook: http://bit.ly/1WjG36m

Follow CBC News on Instagram: http://bit.ly/1Z0iE7O

Subscribe to CBC News on Snapchat: https://bit.ly/3leaWsr

Download the CBC News app for iOS: http://apple.co/25mpsUz

Download the CBC News app for Android: http://bit.ly/1XxuozZ

»»»»»»»»»»»»»»»»»»

For more than 80 years, CBC News has been the source Canadians turn to, to keep them informed about their communities, their country and their world. Through regional and national programming on multiple platforms, including CBC Television, CBC News Network, CBC Radio, CBCNews.ca, mobile and on-demand, CBC News and its internationally recognized team of award-winning journalists deliver the breaking stories, the issues, the analyses and the personalities that matter to Canadians.

Published: 15th Mar 2025 12:14:55 By: CBC NewsCBC Video: Exposing ‘sex-for-rent’ ads targeting students | Marketplace

Sex-for-rent ads are widely available online, but experts call these arrangements illegal and exploitative, targeting young, vulnerable women — often international students. We respond to more than a dozen of these ads, revealing the disturbing trend, confronting the men involved and holding them accountable.

#Housing

00:00 - Responding to ads

09:28 - Hidden camera investigation

14:27 - Confronting landlords

17:56 - What can be done?

https://www.cbc.ca/1.7483773

»»» Subscribe to CBC News to watch more videos: http://bit.ly/1RreYWS

Connect with CBC News Online:

For breaking news, video, audio and in-depth coverage: http://bit.ly/1Z0m6iX

Follow CBC News on TikTok: https://bit.ly/3TnHioe

Follow CBC News on Twitter: http://bit.ly/1sA5P9H

Find CBC News on Facebook: http://bit.ly/1WjG36m

Follow CBC News on Instagram: http://bit.ly/1Z0iE7O

Subscribe to CBC News on Snapchat: https://bit.ly/3leaWsr

Download the CBC News app for iOS: http://apple.co/25mpsUz

Download the CBC News app for Android: http://bit.ly/1XxuozZ

»»»»»»»»»»»»»»»»»»

For more than 80 years, CBC News has been the source Canadians turn to, to keep them informed about their communities, their country and their world. Through regional and national programming on multiple platforms, including CBC Television, CBC News Network, CBC Radio, CBCNews.ca, mobile and on-demand, CBC News and its internationally recognized team of award-winning journalists deliver the breaking stories, the issues, the analyses and the personalities that matter to Canadians.

THE SECRET COST OF HOUSING

producer/director

JEREMY McDONALD

associate producers

SNEHA AGRAWAL

TOMI JOSEPH RAJI

reporter

ASHA TOMLINSON

editor

SIMON PARUBCHAK

camera

DAVID MACINTOSH

OUSAMA FARAG

additional footage

CITY OF BRAMPTON

audio

IGAL PETEL

art director

DAVID ABRAHAMS

graphic designer

YOUSEF ABDEL RAHMAN

media management

ASTORIA LUZZI

social media producers

CAROLINE GDYCZYNSKI

BRITT PURDY

colour correction

KYLE J. SMITH

sound mix

MARIANA HUTTEN

resource coordinators

MARC CORMIER

DRAGAN MARICIC

news rollout associate producer

DEXTER McMILLAN

promo producer

GREG SADLER

packaging producer

LINDA SIBONY

senior producer

TIFFANY FOXCROFT

FIRST BROADCAST March 14, 2025

Published: 15th Mar 2025 12:00:02 By: CBC NewsCBC Video: Political Pulse Panel: PM Carney and cabinet sworn in with election campaign likely days away

The Political Pulse Panel discusses Day 1 of Mark Carney as Canada's 24th prime minister.

»»» Subscribe to CBC News to watch more videos: http://bit.ly/1RreYWS

Connect with CBC News Online:

For breaking news, video, audio and in-depth coverage: http://bit.ly/1Z0m6iX

Follow CBC News on TikTok: https://bit.ly/3TnHioe

Follow CBC News on Twitter: http://bit.ly/1sA5P9H

Find CBC News on Facebook: http://bit.ly/1WjG36m

Follow CBC News on Instagram: http://bit.ly/1Z0iE7O

Subscribe to CBC News on Snapchat: https://bit.ly/3leaWsr

Download the CBC News app for iOS: http://apple.co/25mpsUz

Download the CBC News app for Android: http://bit.ly/1XxuozZ

»»»»»»»»»»»»»»»»»»

For more than 80 years, CBC News has been the source Canadians turn to, to keep them informed about their communities, their country and their world. Through regional and national programming on multiple platforms, including CBC Television, CBC News Network, CBC Radio, CBCNews.ca, mobile and on-demand, CBC News and its internationally recognized team of award-winning journalists deliver the breaking stories, the issues, the analyses and the personalities that matter to Canadians.

Published: 14th Mar 2025 11:44:06 By: CBC News

International Video: Will.I.Am on AI, Tesla and the future

The Black Eyed Peas frontman and The Voice star Will.I.Am is a firm believer in technological advancement, even founding his own AI company.

[Subscribe: https://bit.ly/C4_News_Subscribe]

Now his platform FYI is being put into cars - complete with personalised radio stations and voice assistants that can talk you through the news. This embrace of AI makes him an outlier in an industry where other musicians have warned about its dangers - accusing it of trying to replace them or even stealing their music.

We spoke to Will.I.Am and asked him what he would say to artists who think AI is a threat.

-------

Get more news at our site - https://www.channel4.com/news/

Follow us:

TikTok - https://www.tiktok.com/@c4news

Instagram - https://www.instagram.com/channel4news/

Twitter - https://twitter.com/Channel4News

Facebook - https://www.facebook.com/Channel4News/

Published: 14th Mar 2025 07:46:36 By: Channel 4 NewsInternational Video: Mark Carney sworn in as new Canadian prime minister

Mark Carney has been sworn in as the new Canadian prime minister at a ceremony in Ottawa.

[Subscribe: https://bit.ly/C4_News_Subscribe]

The former Bank of England governor has replaced Justin Trudeau as the leader of the Liberal Party after being voted in by party members last weekend.

-------

Get more news at our site - https://www.channel4.com/news/

Follow us:

TikTok - https://www.tiktok.com/@c4news

Instagram - https://www.instagram.com/channel4news/

Twitter - https://twitter.com/Channel4News

Facebook - https://www.facebook.com/Channel4News/

Published: 14th Mar 2025 05:24:02 By: Channel 4 NewsInternational Video: Hamas says it will release US-Israeli hostage

Hamas says it has agreed to release Edan Alexander, a 21-year-old American-Israeli hostage - along with the bodies of four dual US nationals - if Israel begins the second phase of ceasefire talks.

[Subscribe: https://bit.ly/C4_News_Subscribe]

Israel described it as 'psychological warfare'.

-------

Get more news at our site - https://www.channel4.com/news/

Follow us:

TikTok - https://www.tiktok.com/@c4news

Instagram - https://www.instagram.com/channel4news/

Twitter - https://twitter.com/Channel4News

Facebook - https://www.facebook.com/Channel4News/

Published: 14th Mar 2025 05:23:11 By: Channel 4 NewsInternational Video: Duterte at ICC in the Hague

The former Philippines president Rodrigo Duterte has appeared via video link at the International Criminal Court in The Hague.

[Subscribe: https://bit.ly/C4_News_Subscribe]

Duterte faces charges of crimes against humanity linked to the deadly 'war on drugs ' which he oversaw during his time in power.

-------

Get more news at our site - https://www.channel4.com/news/

Follow us:

TikTok - https://www.tiktok.com/@c4news

Instagram - https://www.instagram.com/channel4news/

Twitter - https://twitter.com/Channel4News

Facebook - https://www.facebook.com/Channel4News/

Published: 14th Mar 2025 05:22:10 By: Channel 4 NewsInternational Video: American Airlines jet catches fire

178 passengers and crew managed to escape from an American Airlines jet which caught fire after an engine fault.

[Subscribe: https://bit.ly/C4_News_Subscribe]

The Boeing 737-800 was on its way to Dallas Fort Worth - but diverted to Denver after the crew reported 'engine vibrations'. 12 people were treated for minor injuries.

-------

Get more news at our site - https://www.channel4.com/news/

Follow us:

TikTok - https://www.tiktok.com/@c4news

Instagram - https://www.instagram.com/channel4news/

Twitter - https://twitter.com/Channel4News

Facebook - https://www.facebook.com/Channel4News/

Published: 14th Mar 2025 01:39:01 By: Channel 4 News