Live

France24 English News Live StreamGlobal News

Global News Video PlaylistPBS

PBS News Video PlaylistNavigating the Premier Digital Gaming Platforms for Modern Players

The landscape of digital wagering in the Emerald Isle has evolved into a highly competitive and sophisticated market, offering enthusiasts an unprecedented array of entertainment options. With hundreds of platforms vying for attention, navigating this expansive ecosystem requires a discerning eye and a comprehensive understanding of what constitutes a top-tier gaming experience. The market has grown substantially, moving away from rudimentary interfaces to immersive, high-definition environments that rival physical establishments. For players seeking the most reliable and engaging destinations, understanding the specific criteria that elevate a platform from average to exceptional is absolutely paramount. This involves scrutinizing everything from regulatory compliance and game libraries to the efficiency of financial transactions and the responsiveness of customer support teams.

Among the frontrunners in this digital revolution is Betalright, a platform that has rapidly established itself as a leading destination since its launch in 2020. What immediately captures the attention of both novice and veteran players is its sleek, intuitive interface designed for seamless navigation. However, the true strength of Betalright lies beneath the surface. The platform boasts an impressive catalog of over 3,200 games, sourced from industry giants such as NetEnt, Microgaming, Evolution Gaming, and Pragmatic Play. This massive library ensures that every preference, from classic fruit machines to complex video slots and immersive live dealer tables, is catered to. Furthermore, the platform offers a generous welcome package, typically matching a player's initial deposit up to €500, complemented by 100 complimentary spins. Crucially, Betalright operates under a stringent Malta Gaming Authority (MGA) license and prioritizes swift withdrawal processing, often completing transactions within 24 to 48 hours.

Another standout in the premium gaming sector is Legendplay, a platform established in 2019 that prioritizes elegance and high-quality user experiences. This MGA-licensed operator has cultivated a reputation among discerning players who value curated content over sheer volume. With a library of approximately 2,800 top-tier titles, Legendplay frequently offers exclusive early access to highly anticipated new releases. Their promotional structure is particularly attractive, featuring a 150% match on initial deposits up to €400. For high-volume players, the VIP program delivers personalized bonuses, elevated withdrawal limits, and dedicated account management.

When evaluating these platforms, it is crucial to consider the various elements that contribute to a secure and enjoyable environment. Players should always conduct their own due diligence before committing funds to any platform. Here are several critical factors to consider during your evaluation process:

- The presence of a recognized and valid regulatory license, such as those from the MGA or UKGC.

- The diversity and quality of the game library, including partnerships with reputable software developers.

- The transparency and fairness of bonus terms, particularly the wagering requirements.

- The variety of supported payment methods and the historical speed of their withdrawal processing.

- The availability and responsiveness of customer support, ideally offering 24/7 live chat.

Security and regulatory compliance are non-negotiable aspects of any reputable platform. Royalistplay distinguishes itself in this regard by holding dual licenses from both the UK Gambling Commission and the Malta Gaming Authority. This exceptional level of regulatory oversight provides players with unparalleled peace of mind. Royalistplay pairs this security with a robust library of over 2,500 games, placing a special emphasis on progressive jackpot slots where substantial prize pools accumulate. Their welcome offer is equally balanced, providing a 100% match up to €300 alongside a notably generous allocation of 200 complimentary spins.

The mobile gaming experience has also become a critical battleground for these platforms. The majority of wagering activity now occurs on smartphones and tablets, necessitating flawless mobile optimization. Leading platforms have invested heavily in responsive web design, ensuring their sites adapt perfectly to any screen size without the need for dedicated applications. This mobile-first approach guarantees that players have access to their favorite games, banking functions, and customer support channels from anywhere, at any time. The seamless integration of these features across desktop and mobile environments is a hallmark of a truly premier gaming destination.

In conclusion, finding the ideal online casino ireland platform requires balancing personal gaming preferences with objective indicators of quality and security. Whether you prioritize a massive game library, unparalleled regulatory protection, or rapid financial transactions, the current market offers tailored solutions. By focusing on established platforms with proven track records, robust licensing, and fair promotional structures, players can ensure their digital gaming experience is both thrilling and secure. Always remember that wagering should remain a form of entertainment, and utilizing responsible gaming tools is essential for maintaining a healthy relationship with these digital platforms.

Newsroom Features

MWC Barcelona 2026: Inside “The IQ Era” of Connected Intelligence

See Special Report: MWC Barcelona 2026: Inside “The IQ Era” of Connected Intelligence

Published Saturday February 28, 2026

President Trump’s 2026 State of the Union: Key Moments, Party Reactions, and What It Means for the Midterms

See Special Report: President Trump’s 2026 State of the Union: Key Moments, Party Reactions, and What It Means for the Midterms

Published Wednesday February 25, 2026

2026 Winter Games & Paralympics: Global Triumphs, Breakthrough Moments and The Road to the French Alps 2030

See Special Report: 2026 Winter Games & Paralympics: Global Triumphs, Breakthrough Moments and The Road to the French Alps 2030

Published Tuesday February 24, 2026

The Fat Tuesday-Ash Wednesday Connection: From Feast to Reflection

See Special Report: The Fat Tuesday-Ash Wednesday Connection: From Feast to Reflection

Published Friday February 20, 2026

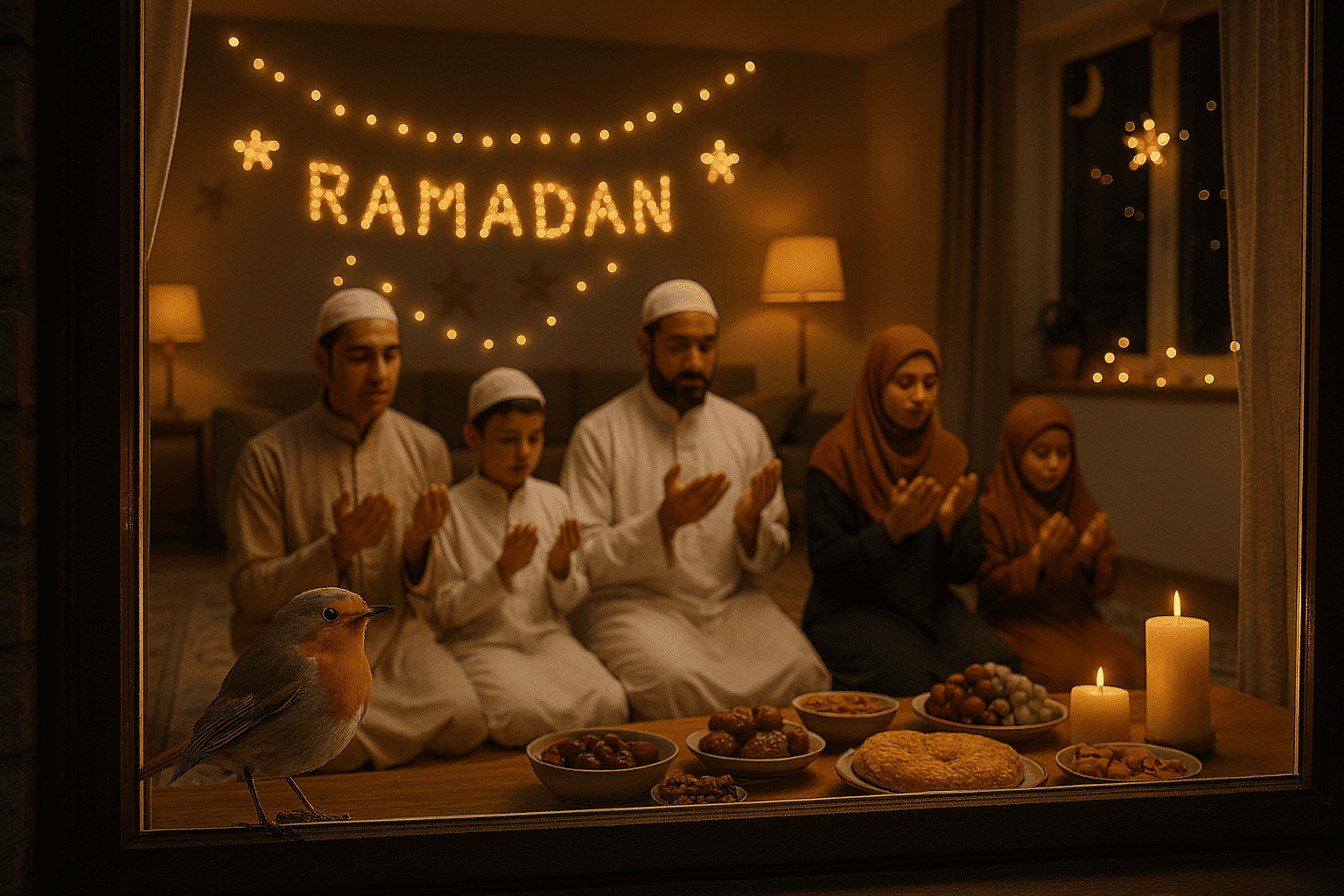

Ramadan 2026: A Month of Fasting, Faith, and Global Community

See Special Report: Ramadan 2026: A Month of Fasting, Faith, and Global Community

Published Wednesday February 18, 2026

Timeless Cabinet Shades That Never Go Out of Style

See Contributor Story: Timeless Cabinet Shades That Never Go Out of Style

Published Wednesday March 04, 2026

5 Simple Things You Can Do to Secure Your Home

See Contributor Story: 5 Simple Things You Can Do to Secure Your Home

Published Tuesday March 03, 2026

Is It Dangerous to Drive Beside a Semi-Truck?

See Contributor Story: Is It Dangerous to Drive Beside a Semi-Truck?

Published Monday March 02, 2026

How To Ensure Your Quinceanera Goes Over Perfectly

See Contributor Story: How To Ensure Your Quinceanera Goes Over Perfectly

Published Sunday March 01, 2026

Exploring When To Use Hard Chrome Plating

See Contributor Story: Exploring When To Use Hard Chrome Plating

Published Saturday February 28, 2026